Fire-fighting vehicles with powder and nitrogen (ASPA)

Intended use:

The fire-fighting vehicles with dust and nitrogen are intended to equip fire-fighting units for interventions to extinguish large fires in economic and social objectives (petrochemical, energy, airports, etc.).

By its construction and equipment, the machines can work independently, ensuring the delivery of the extinguishing powder through cannon pipes and self-protection pipes equipped with manual pipes.

Chassis:

-

Double cabin with 1 + 5 seats

-

Payload: 7100-7500 kg

-

Specific engine power: 16-18 HP/To

-

Traction formula: 6×6

Bodywork:

-

made of corrosion-resistant steel profiles or stainless steel, coated with aluminium sheet applied by gluing

-

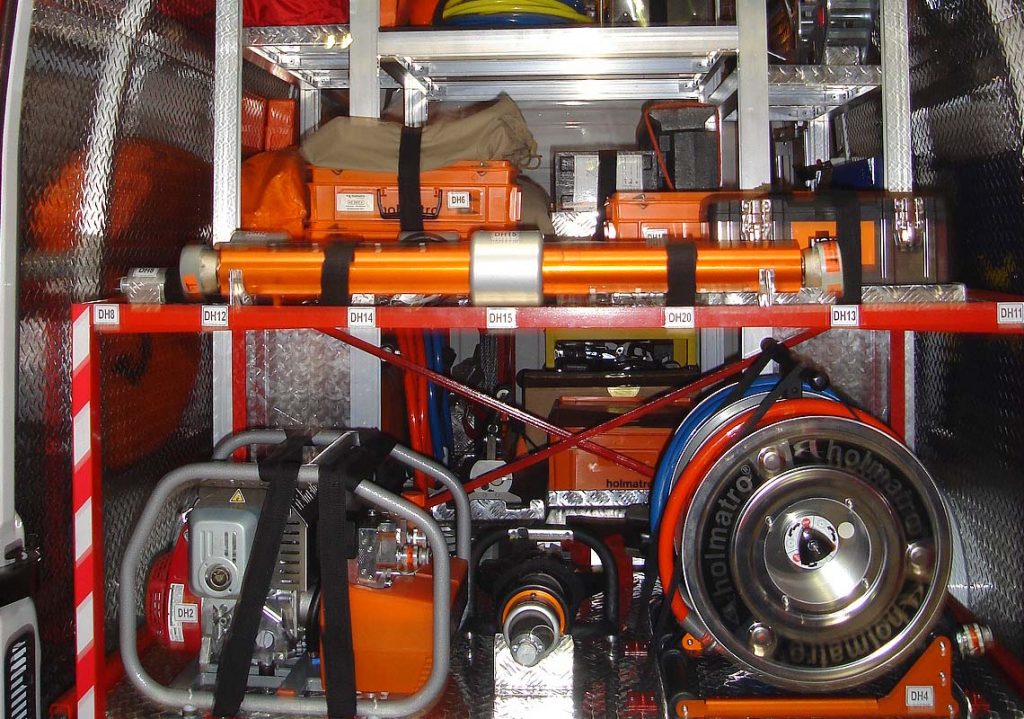

8 blinds are mounted on the sides, allowing access to the powder and nitrogen fire extinguishing system

Technical characteristics of the dust and nitrogen extinguishing system:

-

4 tanks with a capacity of 1250 kg; maximum pressure: 18 bar

-

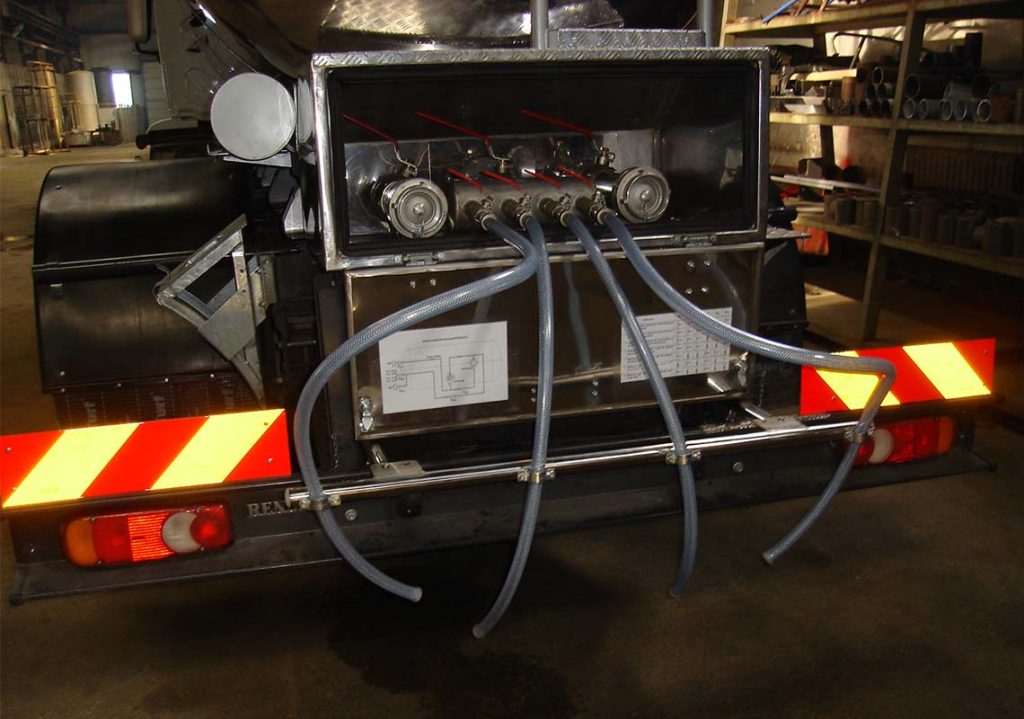

16 gas cylinders connected by flexible tubes to 4 manifolds

The cylinders are charged at a pressure of 130-150 bar, grouped in 4 modules (all foldable) of 4 pieces each.

-

1 control cylinder at 130-150 bar pressure

-

4 pressure reducers (to reduce nitrogen pressure from 130-150 bar to 8-10 bar (discharge pressure)

-

4 discharge outlets with type C connector placed 2 left and 2 right between the cabin and the installation compartment

-

1 deluge gun with 2 delivery pipes, hydrostatically operated from the cabin

-

Horizontal deluge gun rotation: 360o

-

Vertical cannon rotation: -10o ¸ +80o

The control panel, located in the cabin, provides command and control of the powder plant.

Close to the control panel is the electrical control panel for operating the solenoid valves controlling the pneumatic cylinders at the outlet valves in each tank, the powder outlet valve on the gun and the valve on the self-protection side pipes.